HDGI EARTHING ELECTRODE

SALIENT FEATURES

- Special High Grade Zinc Protective Coating of 86 microns+ as per IS Standards.

- Made from Low Carbon High Quality Mild Steel Pipes (ISI Marked)

- Hot Dip Galvanization of Iron makes it a Rust Proof Electrode

- Lower Resistance results in Better Conductivity

- Larger Surface Area for Higher Fault Current Dissipation

- Higher Strength, Maintenance Free & Long Service Life

- Aesthetic and Unique Design

- Easy and Fast Installation

- Moisture Booster Chemical Bag provided for Low Earth Resistance

- Cost-Effective in Comparison to Pure Copper & Copper Bonded Electrodes

- LATH Brand Name, Model Number, Diameter, Length are Laser Marked

- Available along with Test cum Guarantee Certificate and Earth Pit Display Label

WHY LATH ?

- 10 YEARS REPLACEMENT AND PERFORMANCE GUARANTEE

- Minimum Wall Thickness 3mm for Outer Diameter (OD) 48mm and 3.6mm for OD >76mm

- Minimum 86 Microns+ Protective Zinc Coating prevents Rusting and Corrosion (No Zinc Electroplating)

- Made using only ADOR or ESAB MIG Welding & its Consumables

- Full Inner Strip, Size same as Top Terminal (Can be Cut & Checked)

- Bottom Welded Inner Strip (Visible at Bottom)

- Highly Conductive Compound Filled instead of Cheaper Spurious Materials

- All our Products are Laser Marked as a Testimonial of Performance & Guarantee

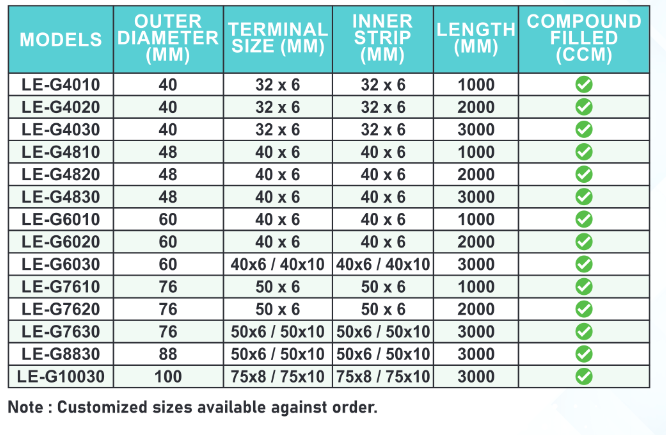

PRODUCT SPECIFICATION

TESTS PASSED

IN-HOUSE LABORATORY

- Visual Check

- Adhesion Test (Wt of Hammer 210 grams)

- Mass of Zinc Coating Test (>610 grams/m2)

- Preece Test (for Coating Uniformity)

Meets the requirement of IS 4759, IS 2629, ASTM 123, BS 729.