COPPER BONDED LIGHTNING ARRESTOR

A Conventional lightning arrestor or Franklin rod is a metal rod mounted on a structure and intended to

protect the structure from a lightning strike. Lightning rods are also called finials, air terminals, or strike

termination devices.

SAILENT FEATURES

- Permanent Molecular Bonding of 99.9% Pure Electrolytic Copper

- Low Carbon Steel Core for unmatched Tensile Strength

- Minimum Copper Coating of 100 microns. can be increased to 254 microns+

- Cold-Rolled Threads with Continuous. Unbroken Grain flows preserve Copper Coating and are

Stronger than Cut Threads (for Threaded Rods) - Efficient discharge path for lightning current, Low Resistance Guaranteed

- Aesthetic and Unique Design

- Maintenance Free and maximum Resistance to corrosion

- Cost-Effective in comparison to Pure Copper Lightning Arrestor

- Robust construction for enhanced Service Life

- Easy installation and maintenance

- Protect the building from damage and any kind of electrical hazards.

- Suitable for various applications and environments

- Copper Bonding will not Crack when bent

- PVC or Metal Base Plate available as per requirement

- LATH Brand Name, Model Number, Diameter. Length are Laser Marked

- Available along with Test cum Guarantee Certificate

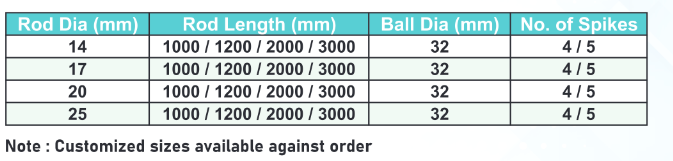

DIMENSION CHART

WHY LATH ?

- In-house Cold Drawn Bright Round processing facility for Stringent Quality Control

- ln-house Cold Rolled Thread facility to preserve copper coating and provide more in comparison to

cut threads - Raw Materials sourced from Integrated Steel Producers i.e. JSW & Vizag Steel Plant (RINL) only.

No Minus Tolerance on Diameter of the Rod i.e, 17.2mm means 17.2mm not 16mm - Only ADOR or ESAB MIG Welding & its Consumables are used in Welding

- Have Minimum 100 Microns + Copper Bonding prevents Rusting and Corrosion (No False Claim of

Higher Copper Coating, Coating available as Committed) - Laser Marked as a Testimonial of Performance Guarantee.

TESTS PASSED

IN-HOUSE LABORATORY

- Tensile Strength (>600 N/mm”)

- Bend Test (No Cracks or Deformation)

- Adhesion Test (Knife Test) No Peel Off

- Cooper Plating Thickness (minimum 100 microns+)

Meets the requirement of IS 3043, IEC 62305