COPPER BONDED STRIPS

SALIENT FEATURES

- 99.9% Pure Electrolytic Copper bonding of minimum 100 microns

- Smooth and Uniform finish

- Copper Bonding will not Crack when Bent

- High Dimensional Stability

- Good Electrical and Thermal Conductivity

- Maintenance Free

- Better Protection against Corrosion

- Cheaper than Pure Copper and HDGI Strips

- Suitable for Electrical Earthing & Lightning Protection Application

- On-Slte Installation Is Easy.

- Available along with Test Certificate

WHY LATH?

- ln-house Copper Plating facility for Stringent Quality Control

- High Quality Raw Materials sourced from reputed Integrated Steel Producers i.e. JSW, Vizag Steel Plant (RINL) and SAIL only

- No Minus Tolerance on width and thickness of the Strip. Le, 50 mm means 50mm not 48 mm

- Have Minimum 100 Microns+ Copper Coating prevents Rusting and Corrosion.

- Laser Marked as a Testimonial of Guaranteed Performance.

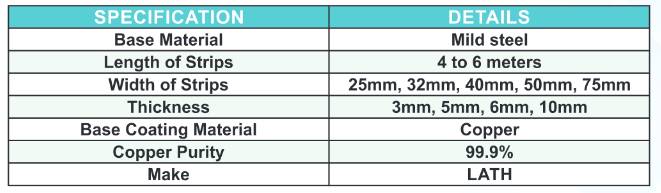

TECHNICAL SPECIFICATION

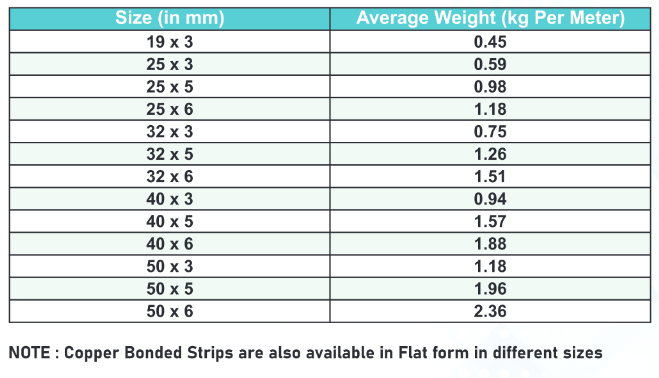

WEIGHT CHART

TESTS PASSED

IN-HOUSE LABORATORY

- Tensile Strength (>600 N/mm2)

- Bend Test (No Cracks or Deformation)

- Adhesion Test (Knife Test) No Peel Off

- Cooper Plating Thickness (100 microns ~i-)