CABLE TRAYS

SALIENT FEATURES

- Improved Cable Protection

- Enhanced Cable Organization

- Durable & Reduced Installation Time

- Instantly Visible for Maintenance Checks

- Ease of Changing Cables

- Increased Flexibility

- Cost-Effectiveness

- Well Designed & Perfect Finish

- Superior Resistance to Corrosion

- Excellent Strength-to-Welght Ratio

- Withstands High Temperatures

- Low Thermal Expansion

- Improved Safety

- Available in Galvanised Iron. Aluminium & Stainless Steel

- Several Options Powder-Coated, Hot-Dip Galvanized. Painted & Pre-Galvanized

- Available along with Test Certificate

WHY LATH?

- ln-house Hot Dip Galvanising Facility for Stringent Quality Control

- High Quality Raw Materials (ISI Marked) Sourced from Reputed Integrated Steel Producers i.e. JSW & Vizag Steel Plant (RINL) and SAIL only

- No Minus Tolerance on Dimension and Thickness of the Strip i.e, 25mm means 25mm not 24mm

- Have Minimum 86 Microns+ Zinc Coating using In House Hot Dip Galvanization Process prevents

- Rusting and Corrosion (No Zinc Electroplating)

- All our Products are Laser Marked as a Testimonial of Performance & Guarantee

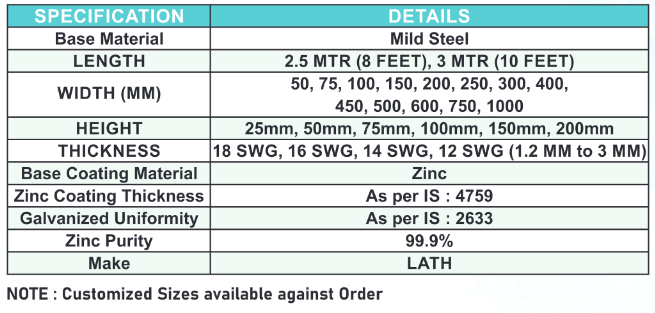

TECHNICAL SPECIFICATION

TESTS PASSED

IN-HOUSE LABORATORY (For HDGI Cable Trays)

- Visual Check

- Adhesion Test (Wt of Hammer 210 grams)

- Mass of Zinc Coating Test (>610 grams/m”)

- Preece Test (for Coating Uniformity)

Meets the requirement of IS 2062, IS 4759, IS 2629, IS 3043