HDGI EARTH PLATE

SALIENT FEATURES

- Hot Dipped Galvanized Iron (HDGI) Earth Plates are Coated with a layer of Special High-Grade

- Zinc as per IS Standards

- Smooth, Uniform and Continuous Finish

- Connected Strip Design Improves the overall Conductivity of the Earth Plate.

- Better Electrical and Thermal Conductivity

- Excellent Corrosion Resistance.

- Suitable for Electrical Earthing

- HDGI Earth Plates are cheaper than Copper Earth Plates

- Provide a long-lasting Earthing Solution in places where driving Earth Rods I Electrodes might be

Impractlcal. - On-site Installation is easy.

- Versatile Application is Industrial, commercial. consumer etc.

- LATH Brand Name, Model Number. Diameter. Length are Laser Marked

- Available along with Test cum Guarantee Certificate and Earth Pit Display Label

WHY LATH ?

- 10 YEARS REPLACEMENT AND PERFORMANCE GUARANTEE

- In-house Hot Dip Galvanising facility for Stringent Quality Control

- High Quality Raw Materials (ISI Marked) sourced from reputed Integrated Steel Producers i.e. JSW & Vizag Steel Plant (RINL) and SAIL only

- No Minus Tolerance on dimension and thickness of the Plate. i.e, 600mm (24″) means 600mm (24″) not 575mm (23″)

- Have Minimum 86 Microns + Zinc Coating using In House Hot Dip Galvanization Process prevents Rusting and Corrosion (No Zinc Electroplating)

- All our Products are Laser Marked as a Testimonial of Performance & Guarantee.

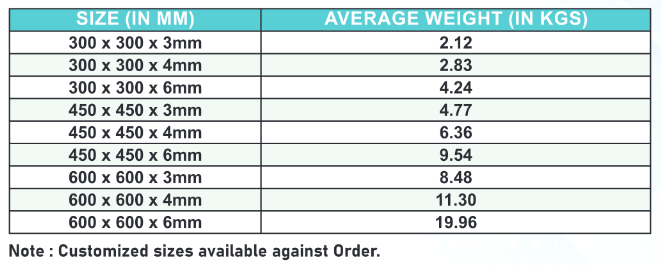

WEIGHT CHART

TESTS PASSED

IN-HOUSE LABORATORY

- Visual Check

- Adhesion Test (Wt of Hammer 210 grams)

- Mass of Zinc Coating Test (>610 grams/m2)

- Preece Test (for Coating Uniformity)

Meets the requirement of IS 2062, IS 4759, IS 2629, IS 3043