COPPER BONDED SOLID EARTH ROD

SALIENT FEATURES

- Permanent Molecular Bonding of 99.9% Pure Electrolytic Copper

- Low Carbon Steel Core for Greater Tensile Strength

- Copper Bonding (100 microns+ minimum | 254 microns+)

- Minimum Copper Coating of 254 Microns (10 Mil) on Rods Listed to UL467

- Cold-Rolled Threads with Continuous, Unbroken Grain flows preserve Copper Coating and are Stronger than Cut Threads (for Threaded Rods)

- Maintenance Free and Corrosion Resistant

- Low Resistance Guaranteed

- High Fault Current Capacity

- Cost-Effective & Long Service Life

- Deep Driving Capability

- Copper Bonding will not Crack when Bent or Tear when Driving

- LATH Brand Name, Model Number, Diameter, Length are Laser Marked

- Available along with Test cum Guarantee Certificate and Earth Pit Display Label

WHY LATH?

- 10 YEARS REPLACEMENT AND PERFORMANCE GUARANTEE".

- In-house Cold Drawn Bright Round processing facility for Stringent Quality Control.

- Raw Materials sourced from Integrated Steel Producers i.e. JSW & Vizag Steel Plant (RINL) only.

- No Minus Tolerance on Diameter and Length of the Rod i.e, 17.2mm means 17.2mm not 16mm.

- Clamp is fully welded using only ADOR or ESAB MIG Welding & its Consumables.

- Having Minimum 100 Microns + Copper Bonding prevents Rusting and Corrosion (No False Claim of Higher Copper Coating, Coating available as Committed).

- All our Products are Laser Marked as a Testimonial of Performance & Guarantee.

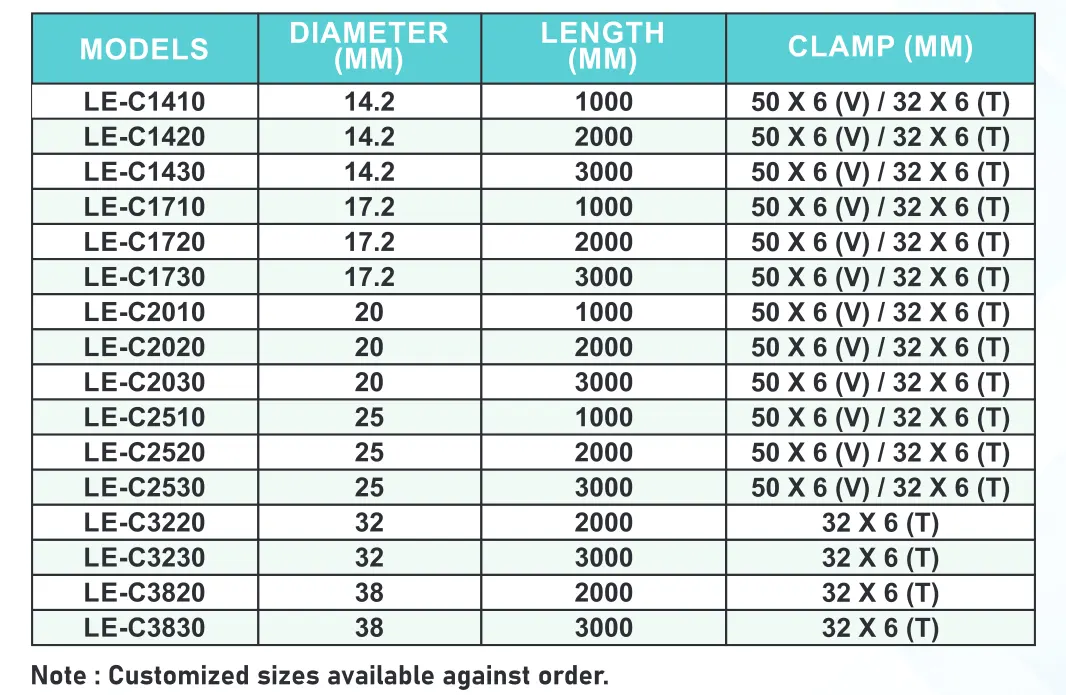

PRODUCT SPECIFICATION

TESTS PASSED

CPRI, BANGALORE

- Tested Short-time withstand current and Peak withstand current

(15kA RMS for 1.03 & 37.5kA Peak)

UL, BANGALORE (U L467)

- Thickness of Protective Coating test (254 microns+)

- Adherence of Coating Test (No Peel Off)

- Bending Test (No Cracks)

NABL ACCREDITED LABORATORY

- Bend Test (No Cracks or Deformation)

- Adhesion Test (Knife Test) No Peel Off

- Cooper Plating Thickness (254 microns+)

Meets the requirement of IS 3043, IEC 62561-2 and UL467